Blog Layout

What Are Lathes? History, Components, and Uses

Nov 13, 2019

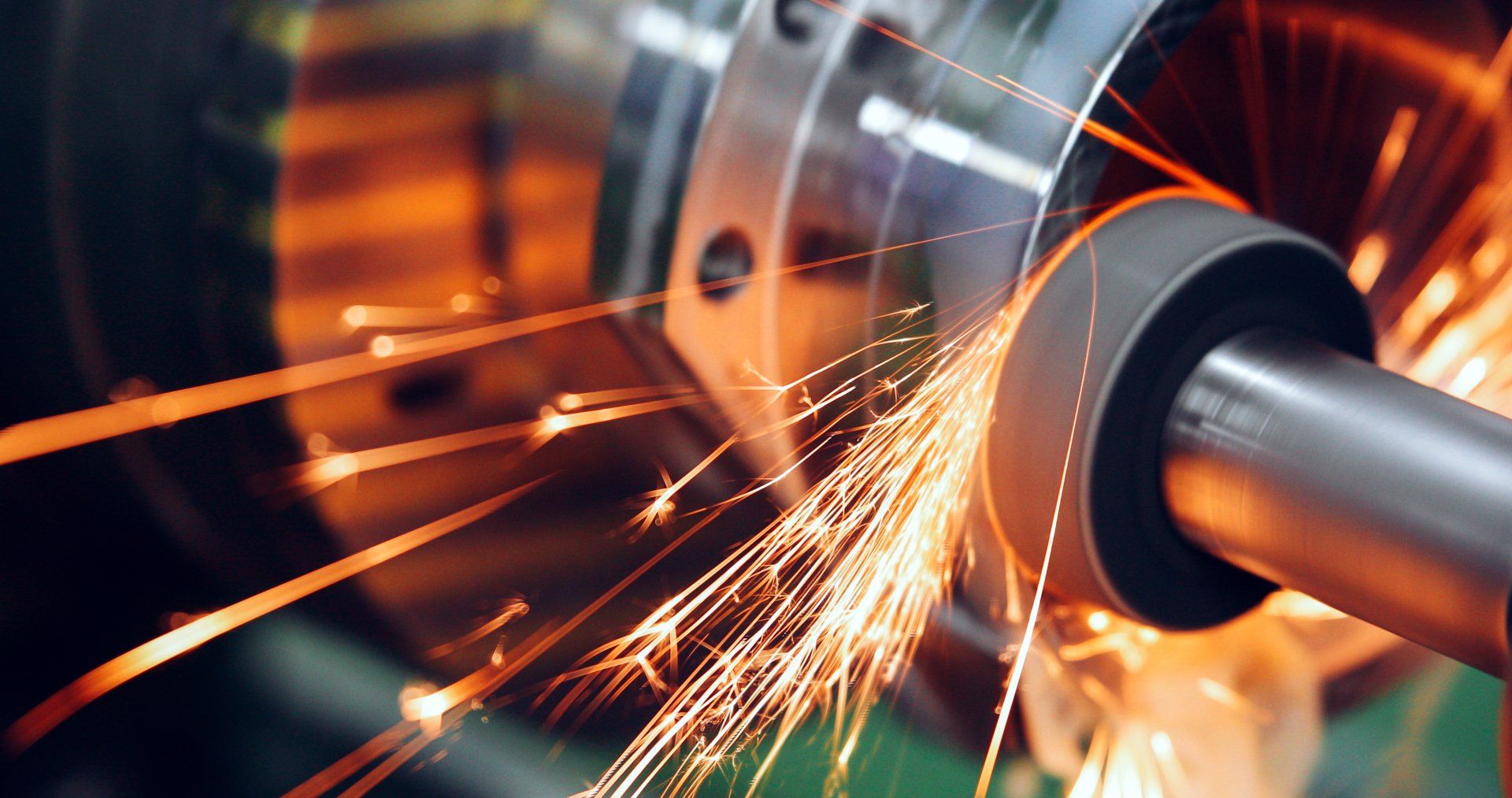

Lathes are versatile machines used for boring, drilling, grooving, and many other applications. They vary in size, shape, and exact application, but are a mainstay in any quality machine or fabrication shop

Lathes are tools that are used to shape wood, metal, or other materials. They’re used for a wide variety of applications and are one of the foundational elements of any quality machine shop. Below we’ll cover what one is and how it’s used more in-depth, as well as its important components.

A Brief History of Lathes

Lathes have been around for centuries, with traces of use as far back as the 13th century B.C. Over the years the design has involved considerably, with an evolution that traces rough hand-operated versions to modern, computer-powered CNC technology.

How Do Lathes Work?

All variants are powered by the same basic premise: a block of material—also known as a workpiece—is rotated at high speed while a blade is pressed against it to shave off excess material and form the desired shape.

On modern CNC-powered lathe models, the blade is held by a high-tech robotic arm that moves on up to seven axes and removes material based on detailed computer models. Older models require varying levels of hand guidance to create the correct shape, with the oldest models requiring the most manual effort.

What Are The Most Basic Lathe Components?

The basic parts of a lathe include the headstock, tailstock, and carriage, though there are many other parts that make up and supplement each of these. The headstock holds the spindle, which in turn holds and spins the workpiece. The tailpiece provides extra support and stabilization opposite the headstock, and the carriage helps guide the tool or blade that is used for shaping.

Each of these parts has more component parts—for example, a cross-slide and tool post are connected to the carriage to hold the blade in place—but these are some of the main component groups.

On CNC models, the carriage is replaced entirely by a tool turret, that is automatically performs all cutting actions based on input from a control panel. The control panel works perfectly with modern CAD programs that are popular with engineers, and can create truly complex designs with the help of a skilled operator.

You might also like

Quick Proto Parts

Quick & Quality

We are available via email or telephone

Location

3727 N Kedzie Ave, Chicago IL

Email

info@quickprotoparts.com

Call

773-463-5026Or Call Toll Free 800-426-6500

© 2024

All Rights Reserved | Quick Proto Parts